Can't promise that I'll test it with an extremely hard material, but I can tell you I'll do my best to stress it out

Super hard nozzles - Test pilots

- antiklesys

- Reactions:

- Posts: 183

- Joined: February 13th, 2016, 8:01 am

- 3D Printer(s): UMO

Re: Super hard nozzles - Test pilots

@Anders if you still have a spare nozzle to send out I'd be glad to test it.

Can't promise that I'll test it with an extremely hard material, but I can tell you I'll do my best to stress it out

Can't promise that I'll test it with an extremely hard material, but I can tell you I'll do my best to stress it out

-

Anders Olsson

- Reactions:

- Posts: 415

- Joined: February 8th, 2016, 8:37 pm

- Location: Uppsala, Sweden

- 3D Printer(s): UM2 UM2E, UM2Go, UM3, Delta Tower, Form 1+, Form 2

- Contact:

Re: Super hard nozzles - Test pilots

Not right now I think, but there will hopefully be more soon

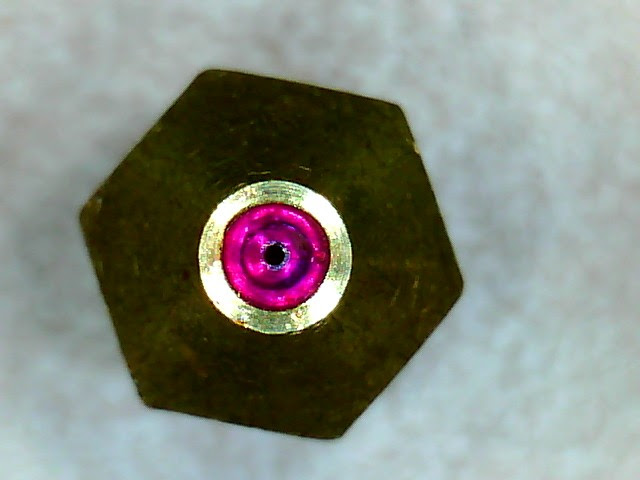

At some point we are going to change from testing to sales, but I would like a few more testers on the one with a professionally made holder for the ruby.

At some point we are going to change from testing to sales, but I would like a few more testers on the one with a professionally made holder for the ruby.

- martin-bienz

- Reactions:

- Posts: 172

- Joined: February 22nd, 2016, 2:42 am

- Location: Switzerland

- 3D Printer(s): Ultimaker Original, prusa i3 mk2

Re: Super hard nozzles - Test pilots

pick me, pick me, either way (testing or sales)Anders Olsson wrote:Not right now I think, but there will hopefully be more soon

At some point we are going to change from testing to sales, but I would like a few more testers on the one with a professionally made holder for the ruby.

- Neotko

- Reactions:

- Posts: 1142

- Joined: February 7th, 2016, 7:02 pm

- Location: Madrid

- 3D Printer(s): UMO+ x2.5

- Contact:

Re: Super hard nozzles - Test pilots

Ok this it's the good area for this.

Bertho the guy that changed the umo feeder (the IRobertI of the UMO's) posted a very interesting think that probably will pass without much notice. A preassure measure system for the filament that goes in the hotend.

https://ultimaker.com/en/community/1989 ... ply-138249

Bertho the guy that changed the umo feeder (the IRobertI of the UMO's) posted a very interesting think that probably will pass without much notice. A preassure measure system for the filament that goes in the hotend.

https://ultimaker.com/en/community/1989 ... ply-138249

- Titus

- Reactions:

- Posts: 252

- Joined: February 9th, 2016, 10:20 pm

- 3D Printer(s): Ultimaker Original+HBK

Re: Super hard nozzles - Test pilots

Available any timeAnders Olsson wrote:Not right now I think, but there will hopefully be more soon

At some point we are going to change from testing to sales, but I would like a few more testers on the one with a professionally made holder for the ruby.

- Amedee

- Reactions:

- Posts: 599

- Joined: February 15th, 2016, 11:10 am

- Location: Brussels, Belgium

- 3D Printer(s): UMO / UMO+

- Contact:

Re: Super hard nozzles - Test pilots

I have not enough time to make in-depth testing, but count me as a customer as I will definitely buy this -- I (almost) always print in 0.4mm, but the main reason I don't use my XT-CF it because I am to lazy to swap nozzles all the time. So having a hard nozzle which works for all materials is absolutely a plus.

- martin-bienz

- Reactions:

- Posts: 172

- Joined: February 22nd, 2016, 2:42 am

- Location: Switzerland

- 3D Printer(s): Ultimaker Original, prusa i3 mk2

Re: Super hard nozzles - Test pilots

Exactly my thinking!Amedee wrote: So having a hard nozzle which works for all materials is absolutely a plus.

- Titus

- Reactions:

- Posts: 252

- Joined: February 9th, 2016, 10:20 pm

- 3D Printer(s): Ultimaker Original+HBK

Re: Super hard nozzles - Test pilots

I haven't tried XT-CF yet(too scared), but half a glowfill roll completely destroyed a nozzle

- LePaul

- Reactions:

- Posts: 4077

- Joined: February 7th, 2016, 10:26 pm

- Location: Bangor, Maine USA

- 3D Printer(s): 24 - Yes I have a problem!

- Contact:

Re: Super hard nozzles - Test pilots

Ha, me too! With no real solid "settings" in Cura to follow, I keep putting it off too.Titus wrote:I haven't tried XT-CF yet(too scared), but half a glowfill roll completely destroyed a nozzle

-

Anders Olsson

- Reactions:

- Posts: 415

- Joined: February 8th, 2016, 8:37 pm

- Location: Uppsala, Sweden

- 3D Printer(s): UM2 UM2E, UM2Go, UM3, Delta Tower, Form 1+, Form 2

- Contact:

Re: Super hard nozzles - Test pilots

That is exactly how I use the ruby.Amedee wrote:So having a hard nozzle which works for all materials is absolutely a plus.

My goal is that it should perform as good as or better than any other nozzle type for all materials, so you who already has received one, don't hesitate use it as you would use your normal nozzle! Any experiences, good or bad, are interesting for me, trying to optimize the parameters.

I haven't used any other nozzle much since I made ruby nozzles because there appears to be no reason going back

That is really interesting, would be very useful to have something like that on the printer when testing nozzles!Neotko wrote:Bertho the guy that changed the umo feeder (the IRobertI of the UMO's) posted a very interesting think that probably will pass without much notice. A preassure measure system for the filament that goes in the hotend.

https://ultimaker.com/en/community/1989 ... ply-138249

I hope that I will have more nozzles ready around easter, but no promises, things always tends to take more time than expected.

- Blizz

- Reactions:

- Posts: 224

- Joined: February 10th, 2016, 2:46 am

- Location: Belgium

- 3D Printer(s): Prusa: XL, MK4, MK3S+-MMU3, MK3S, Mini, SL1S

Re: Super hard nozzles - Test pilots

I bought a big spool from Colorfabb (2.2kgs - cheaper that way) because I have big plans with it.LePaul wrote:Ha, me too! With no real solid "settings" in Cura to follow, I keep putting it off too.Titus wrote:I haven't tried XT-CF yet(too scared), but half a glowfill roll completely destroyed a nozzle

To be honest, I'm putting it off too, a bit scared of it

"Come on Steve, man up!"

Re: Super hard nozzles - Test pilots

very interested as well!

testing/buying, would like to try it with all the exotic materials I have lying around to see what the limits and possibilities are. I have some Protopasta steel filament lying around and love the other metal filled filaments.

testing/buying, would like to try it with all the exotic materials I have lying around to see what the limits and possibilities are. I have some Protopasta steel filament lying around and love the other metal filled filaments.

- Roboduck

- Reactions:

- Posts: 11

- Joined: February 10th, 2016, 1:32 pm

- Location: Minneapolis/St-Paul, Minnesota, USA

- 3D Printer(s): Makerbot Replicator, Ultimaker

Re: Super hard nozzles - Test pilots

I recieved one of Anders' ruby nozzles and have run about a half a spool of ColorFabb XT-CF20 through it so far. I am very happy with the results thus far. I had been using E3D's hardened steel nozzles which worked OK but still started to show some signs of wear after 1-1.5 spools of XT-CF20. One of the big benifits I've seen so far is the better thermal conductivity of the brass nozzle compared to the steel ones. I was able to turn my temps down 5-10 C with the ruby nozzle. It am seeing significantly less stringing (lower temp helps) and more even flow. I haven't taken it out yet to look at the wear but from what I'm hearing it shouldn't be anything significant.

I also had to change material a few times back to regular ColorFabb XT and, maybe its just my imagination, but I am seeing similar benefits with it as well. I'm wondering if the smooth finish of the ruby is helping with flow and preventing the filament from sticking to the tip of the nozzle?

Very happy with the nozzle so far and will update here as I get more results.

Question for those of you cleaning your nozzles for inspection after removing them, what are you using to clean your nozzles? I've just been using a brass wire brush to clean the outside of the nozzle but I was wondering if anyone had a good trick to cleaning out the inside? I've tried the atomic method with mixed success.

I also had to change material a few times back to regular ColorFabb XT and, maybe its just my imagination, but I am seeing similar benefits with it as well. I'm wondering if the smooth finish of the ruby is helping with flow and preventing the filament from sticking to the tip of the nozzle?

Very happy with the nozzle so far and will update here as I get more results.

Question for those of you cleaning your nozzles for inspection after removing them, what are you using to clean your nozzles? I've just been using a brass wire brush to clean the outside of the nozzle but I was wondering if anyone had a good trick to cleaning out the inside? I've tried the atomic method with mixed success.

- Neotko

- Reactions:

- Posts: 1142

- Joined: February 7th, 2016, 7:02 pm

- Location: Madrid

- 3D Printer(s): UMO+ x2.5

- Contact:

Re: Super hard nozzles - Test pilots

I use reverse atomics to clean the nozzle from outside, it leaves a brilliant sexy nozzle  https://ultimaker.com/en/community/1835 ... se-atomics

https://ultimaker.com/en/community/1835 ... se-atomics

- Titus

- Reactions:

- Posts: 252

- Joined: February 9th, 2016, 10:20 pm

- 3D Printer(s): Ultimaker Original+HBK

Re: Super hard nozzles - Test pilots

I was already wondering how an atomic pull would behave on these nozzles.

The reverse might be bad as you could pull the ruby out if the glue fails?(it was glue right? and it probably wont, but still)

The reverse might be bad as you could pull the ruby out if the glue fails?(it was glue right? and it probably wont, but still)